PCB Products

[email protected]

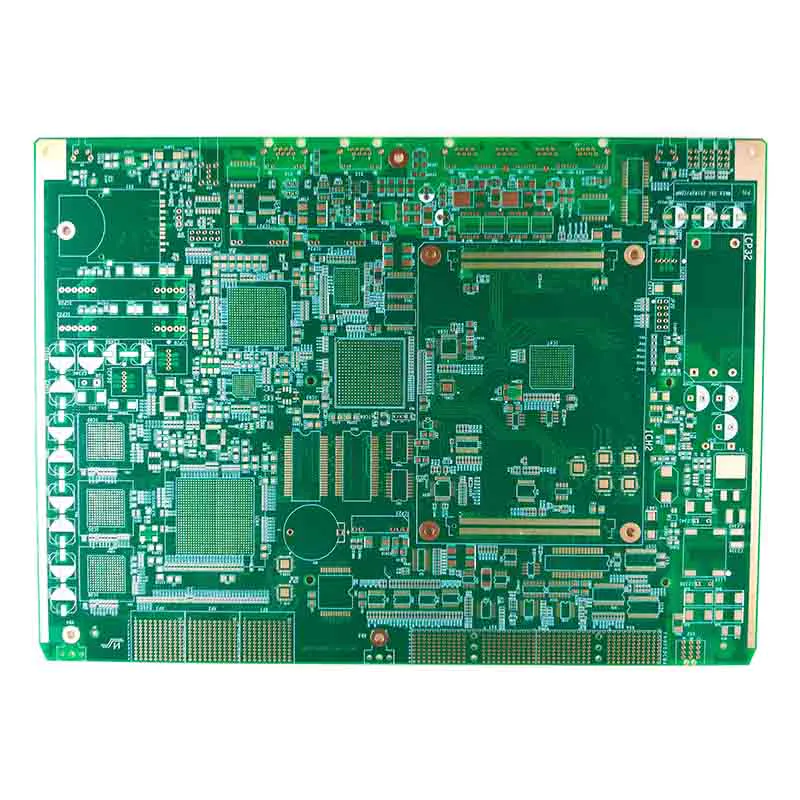

What is PCB?

PCB or printed circuit board is the traditional name for bare boards produced using layout data for installing components.

Printed circuit boards or PCBs are used to mechanically support and electrically connect electronic components using conductive paths, tracks, or signal traces etched from copper sheets laminated on non-conductive substrates. Components are usually soldered onto PCBs to achieve electrical connections and mechanical fixation.

Advantages of PCB

PCB (Printed Circuit Board) has become a very important part of modern electronic devices to some extent. In fact, if you want to disassemble any electronic device in your home, you are likely to encounter one of countless types of PCBs. A basic printed circuit board is composed of a large number of passive and active components. They are connected from one side to the other through traces on the circuit board. It is entirely possible to develop very large circuits on small printed circuit boards using very small electronic components.

But not all PCBs have benefits. Printed circuit boards have multiple advantages, making them the perfect choice for PCB manufacturers of electronic components, instruments, and equipment in various regions.

Keep on reading to find out what they are.

Compact

The feature PCB includes a large number of electronic components. Most of these components are very small in size. Without the help of printed circuit boards, it is almost impossible to connect these components together with wires. A typical printed circuit board provides a simple platform for aligning electronic components in a compressed and efficient manner. This compactness allows for the creation of large and complex electronic circuits in small sizes. This in turn takes up less device space.

Easy to repair and diagnose

One major advantage of printed circuit boards is that they aid in diagnosis for various reasons. The electronic components and their polarity on a correctly designed printed circuit board are clearly marked on the board. This provides convenience for the installation and maintenance processes. During the diagnostic process, the signal path is usually tracked. If the traces are unclear and well-organized, it is difficult to perform this operation.

Immune to Movement

Another noteworthy thing is that all components on the PCB are fixed onto the board. This is done through soldering, and regardless of how the circuit board itself moves, the soldering does not allow them to move. Therefore, electronic circuits (moving or shaking) can be placed in the device without worrying about the displacement of electronic components and the possibility of any subsequent electronic short circuits.

Low electronic noise

Printed circuit boards (properly laid out) can reduce the noise of electronic devices. If the layout is not appropriate, noise may significantly reduce performance. The electrical components on a printed circuit board are organized in a way that reduces the length of the current path between them. This leads to low radiation and pickup of electromagnetic waves, ensuring low crosstalk between components and different traces, which is often a major issue in electronic circuits.

Types of Printed Circuit Boards

PCB board manufacturing is an essential part of all electronic devices, from simple digital watches and handheld games to highly complex satellite systems. PCBs are manufactured in various ways to meet the unique requirements of different industries. They can be manufactured in single-sided, double-sided, and multi-layer configurations as needed.

The following lists three basic types of PCBs used for various industrial, commercial, and household applications.

Single sided - This is the simplest and most commonly used type of PCB. As the name suggests, these PCBs are designed with a single substrate. The design of these PCBs is that all copper traces are etched on one side of the board, and electrical components are etched on the other side. Compared to other types, these PCBs are easier to design and manufacture. They are commonly used in calculators, printers, and sensor products.

Double sided - These types of PCBs are constructed by installing electronic components and copper traces on both sides of the substrate. With the increasing complexity and density of products, the demand for double-sided PCBs is also on the rise. Common applications include controlling relays, converters, power supplies, power monitoring, and transportation systems.

Multilayer - These types of PCBs are characterized by multilayer substrates. Each layer is separated by insulating material. Depending on the complexity of the application, these PCBs can be designed with 4, 6, 8, or 10 layers. These layers can even be increased to 42 layers. Multilayer PCBs are used for extremely complex electronic circuits, such as central fire alarm systems, fiber optic receivers, nuclear detection systems, and space detection equipment. A comprehensive understanding of the basic types of PCBs will help you choose the appropriate circuit board for your application. You can contact the manufacturer to learn about the advantages and disadvantages of each type. In addition, you can inform the manufacturer of your requirements; He can suggest the correct PCB type that is most suitable for your application.

Choose a suitable Chinese PCB manufacturer

PCB or printed circuit board is undoubtedly one of the most popular electronic devices today. In order to comply with this trend, several companies have also started producing PCBs. In fact, a few minutes of searching will tell you how many manufacturers there are on this list. This certainly has an advantage - it makes the market more competitive. However, there are also drawbacks.

Since there are so many choices, you may always feel confused. Therefore, choosing the right company is crucial. Please remember that manufacturing rapid flipping PCB prototypes is a complex task.

The entire process involves many complex technical details. Therefore, you must be very careful about the quality of the experts involved in the project. Usually, PCB manufacturers do not meet your specific requirements. So, this is another factor you must pay attention to.

Finally, finding PCB manufacturers in China for small companies has always been a problem. Those big companies ignore the demands of small companies. Therefore, small companies find it almost necessary to go to some secondary companies, which can damage the quality of PCBs.

However, with https://hitechcircuits.com This issue seems to have ended. Their expert team attaches great importance to the needs of small companies. At the same time, they ensure the highest quality of PCBs.