BGA PCB Assembly

What’s BGA PCB?

[email protected]

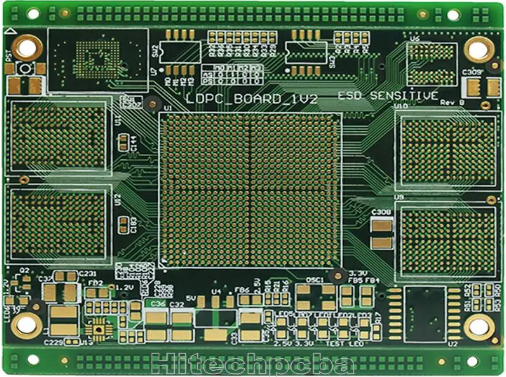

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

BGA PCB

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

BGA Assembly

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

BGA PCB Assembly inspection

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.